Welding wire G3

Hardness [HRc]

33

Purpose

1.2343, 1.2344, 1.7225, Toolox 44

G3 welding wire is primarily intended for welding hot-working steels, but in laser welding it achieves lower hardness than in the TIG process. It has good toughness and elasticity. It is suitable for a wide range of materials. Also suitable for welding polished surfaces, nitriding, etching, etc.

- 1 package Straight wire contains 50 pieces

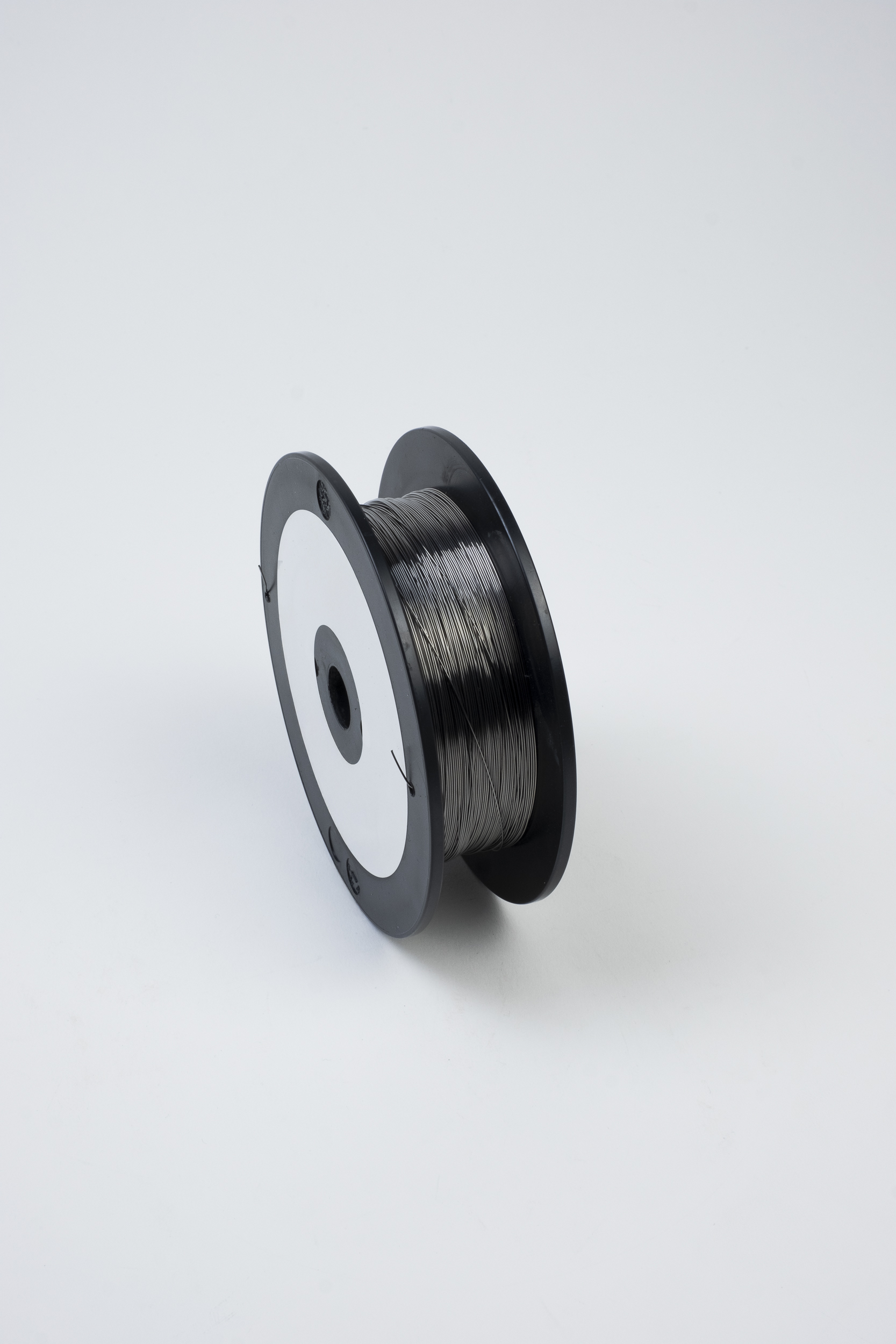

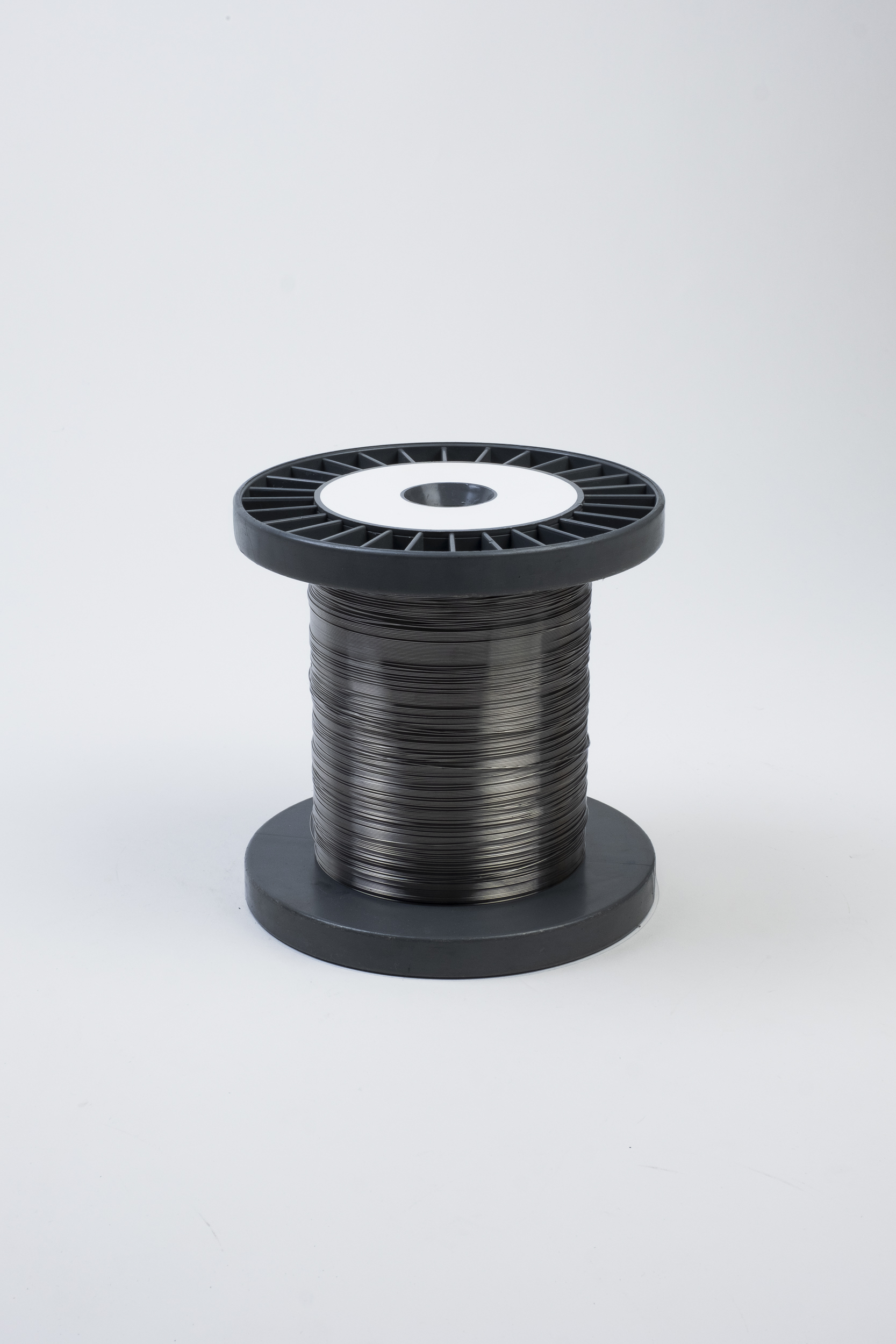

- 1 package Spool wire contains 50 m

Note

Follow general welding guidelines.

Chemical composition

| 0,25 | C |

| 0,5 | Si |

| 0,7 | Mn |

| 5,0 | Cr |

| 4,0 | Mo |

| 0,6 | Ti |

| ostalo | Fe |

Straight wire

| Wire diameter [mm] | 1 piece of wire [g] | 50 pieces of wire [g] | 100 pieces of wire [g] |

| ɸ 0,2 | 0,123 | 6,16 | 12,32 |

| ɸ 0,3 | 0,277 | 13,87 | 27,73 |

| ɸ 0,4 | 0,493 | 24,65 | 49,30 |

| ɸ 0,5 | 0,770 | 38,52 | 77,03 |

| ɸ 0,6 | 1,109 | 55,45 | 110,90 |

| ɸ 0,7 | 1,509 | 75,45 | 150,90 |

| ɸ 0,8 | 1,972 | 98,60 | 197,20 |

Spool

| Wire diameter [mm] | 1m of wire [g] | 50m of wire [g] | 100m of wire [g] |

| ɸ 0,2 | 0,246 | 12,32 | 24,65 |

| ɸ 0,3 | 0,555 | 27,73 | 55,46 |

| ɸ 0,4 | 0,986 | 49,30 | 98,60 |

| ɸ 0,5 | 1,541 | 77,03 | 154,06 |

| ɸ 0,6 | 2,218 | 110,90 | 221,80 |

| ɸ 0,7 | 3,018 | 150,90 | 301,80 |

| ɸ 0,8 | 3,944 | 197,20 | 394,40 |